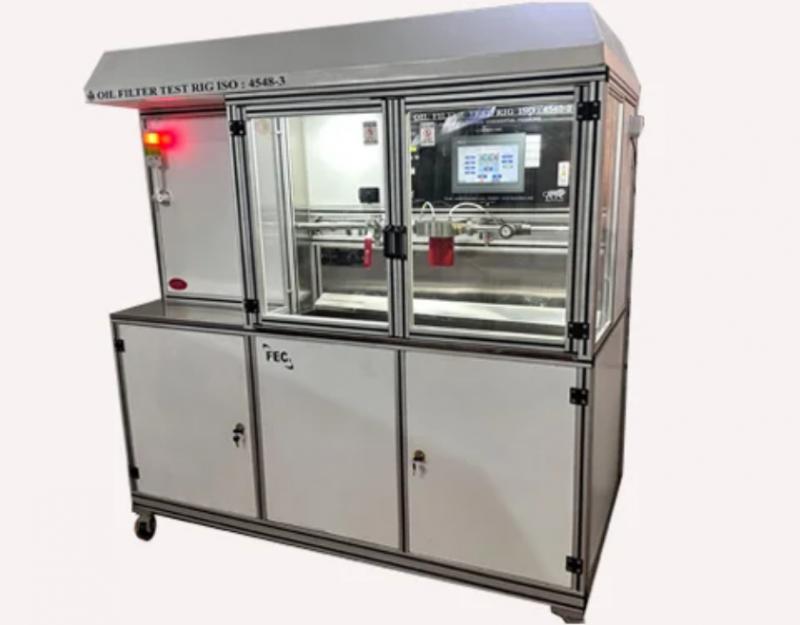

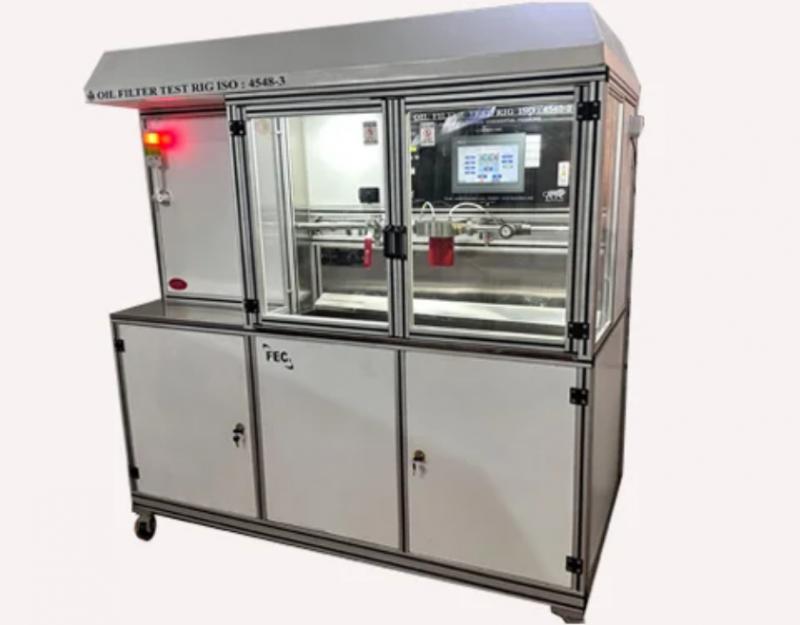

The Oil Filter Collapse Test Rig is designed as per ISO 4548-3 to test the structural strength and collapse pressure of oil filter elements. This test simulates real-world hydraulic conditions where filter elements may fail due to differential pressure spikes.

Constructed using a GI sheet frame with MS pipework and automotive-grade epoxy paint, the unit includes a stainless steel platform with a washbasin-type tray and drainage for cleanliness. The test circuit uses seamless stainless steel or copper piping with smooth bends as per international norms, and a conical SS reservoir for oil storage.

The system includes:

Inlet/outlet pressure gauges

Flow meter for precise setting

Absolute filter media holder

Adjustable oil flow regulator

Specialized pump that does not disturb test particles

Proper lighting for night/dark condition testing

It is ideal for R&D, QA/QC, and production testing of filter collapse pressure capabilities.

Standard: ISO 4548-3

Collapse Pressure Range: Up to 20 bar or as specified

Construction: GI Sheet + MS pipe frame with epoxy paint

Test Tray: Stainless steel upper platform with washbasin-style tray

Test Circuit: Seamless SS/Copper pipes with long bends

Oil Flow Regulation: Manual flow regulator (fine control)

Pump: Non-disruptive to particle characteristics

Reservoir: Stainless steel, conical shape

Indicators: Analog/digital pressure gauges, flow meter

Lighting: LED arrangement for operation in dark environments

Power Supply: 230V, 50 Hz

Used to evaluate structural integrity of oil filters under pressure

Confirms whether filter elements can withstand collapse pressure during system surge or failure

Essential in automotive filter R&D, production validation, and OEM compliance testing

More details:View company website

Its Free

Verify Now