Duplex Engineering Works

Product Range

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:1982

- Main Products: Metal Chains, Resistance Boxes

- Reviews & Rating:

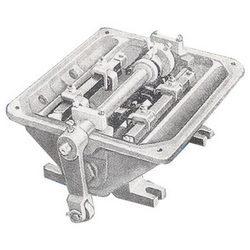

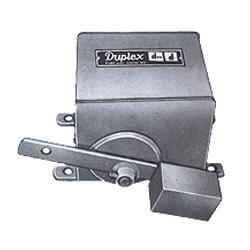

Differential Limit Switches

We hold expertise in manufacturing quality Limit switches (for grabbing motion) which are developed using high grade raw material.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

We hold expertise in manufacturing quality Limit switches (for grabbing motion) which are developed using high grade raw material. These are driven by holding and closing winches which is used in auxiliary circuits for single lever grab control. Our range is mainly used for stopping the closing motor regardless of the height of the grab and starting the holding motor after closing for transition to the hoisting action and also for stopping the holding and closing motors at the highest and lowest grab positions.

Construction:

The switch that we manufacture contains six cam operated switch elements which are used as an auxiliary circuit limit switches. These switches have two shafts which are driven by the holding and closing winches. Our product is designed for heavy duty application, housed in IP-54 degree of protection. The limit switches are 40 amps rated at 500 v. A.C. We have made these using quality cast iron base and cover which are machined to protect against dirt and dust.

Mode of operation:

The N5 and N6 limit switches are the highest and lowest grab positions. The closed and open grab limit positions are supervised by the switches N1 and N4. On the other hand, N2 and N3 initiate the switches operations for single lever grab control.

Installation:

For the installation process and easy accessibility, on one side of the winch space a switch is pest arranged between the drums. These are mounted on a horizontal and a vertical position. The switching equipment and gearing are reached with ease as soon as the cover is removed. The auxiliary shafts are connected to the winch shaft of the grab hoisting gear are best used for driving the switch. A closing winch is connected with a shaft 1 at the differential gear end, and on the other end the holding is jointed to shaft 2 at the same or opposite end of the switch.

the switch is pest arranged to one side of the winch space between the drums, where it should be easily accessible. It can be mounted either in a horizontal or a vertical position. However, the former is preferred since the switching equipment and gearing can be reached more easily when the cover has been removed. Auxiliary shafts connected to the winch. The closing winch is connected to shaft and the holding which

Accessories:

We need a wrench which is used for releasing the lock nut after the adjustments of the cam discs. These wrenches are offered with a switch to our clients as per their demands and requirements. A special wrench is needed to release the locking nut when adjusting the cam discs. This wrench is included with the switch.

Images