Krishnaa Energy Pvt Ltd

Product Range

Fact Sheet

- Location:Tamil Nadu, India

- Year of Establishment:1997

- Business Type:Manufacturer, Exporter

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Electronic Equipments, Energy Meters

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

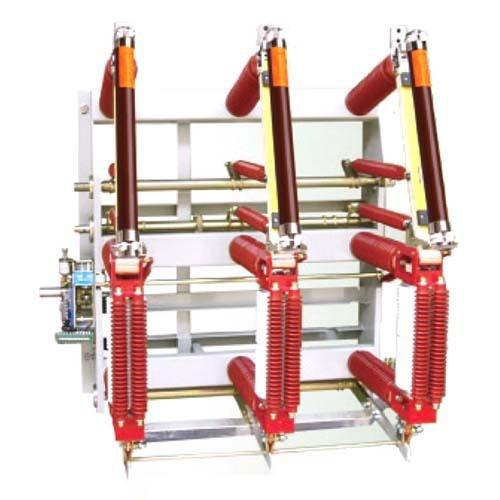

Verify NowOutdoor Kiosk

Krishnaa Energy has established a state-of-the-art facility in manufacturing HT (MV) outdoor kiosk. We are specialized in meeting the technical requirements through design, manufacture, test

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Krishnaa Energy has established a state-of-the-art facility in manufacturing HT (MV) outdoor kiosk. We are specialized in meeting the technical requirements through design, manufacture, test and supply of H.T. switch boards with all accessories for efficient and trouble free operations.

Construction:

The panel's are metal-enclosed, free-standing compartmentalized, Modular type suitable for indoor and outdoor installations. The Panels are dust and vermin proof and the enclosure shall provide a degree of protection of not less than IP- 52 and IP-54.

The Panel boards are fabricated out of adequate thickness mild steel Structural sections. The frames shall be enclosed with cold rolled steel of not less than 2.0 mm thickness. Each cable chamber has cable entry from Top or Bottom with suitable removable gland plates. The cable chamber is provided with suitable supporting arrangement between the gland plate and terminals. All covers, doors and Joints are gasketted using neoprene gaskets.

Busbars:

All the busbars are air insulated and made up of high conductivity, Tin coated copper or Electrolytic grade Aluminium. Busbars have a fault withstand capacity of equivalent to 25 KA/35 Ka/50 kA 1 Sec matching with the rating of the incomer circuit breaker as mentioned or as required. All bus bars are fully screened by means of PVC sleeves in their own compartment running throughout the length of the panel and the busbars are Provided with holes for future expansion. Suitable segregation will be provided in between busbar chamber and adjoining compartments. The busbars will be TP and N, the section of the neutral bus being full Size or Half the size of the phase busbar as per the requirement. The busbar will be PVC sleeved with color strips of red, yellow, blue and black .The busbar will be properly segregated, suitably braced with insulated Supports (DMC/FRP/SMC) placed at appropriate intervals to withstand the electro magnetic stresses during short circuit. Minimum electrical Clearances will be maintained between phase, neutral and body as per IS and IEC standards.

Control wiring:

Panel will be supplied with all internal wiring comprising of PVC insulated 1.1 KV grade, multi strand flexible copper conductor of 1.5 Sq.mm cross section. Wiring associated with a particular phase will be the color of that phase viz. Red, Yellow, or Blue, wiring associated with earthing will be with green color insulation and for neutral it shall be with black color insulation.Wiring will be neatly laid and run on insulated cleats of limited compression type insulated straps. All the cables have crimped terminations and it will be identified by means of glossy plastic ferrules at both ends, showing the wire number as indicated in the submitting control diagrams.

Earthing:

All the metal parts of all equipment supplied with in the panel (including doors and gland plates) other than those forming part of all electric circuit, will be connected by means of independent earth Conductors to continuous copper earth bar of size as required by the client. All the doors in the panels are earthed with the studs welded in the doors.

Labeling:

Labels will be provided to identify every Instrument, or other item of equipment mounted internally and externally. Switch positions will be fully identified. Wording will be clear, concise and unambiguous.The labels will be engraved with white letters in black background. Labeling plays an important role for maintenance of the panel after installation, so care is taken to denote appropriately

Images