Dr Polymers Ltd

Product Range

Fact Sheet

- Location:New Delhi, India

- Year of Establishment:1978

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Turnover:Rs. 50 - 500 Crore

(or USD 10 Million - USD 100 Million) - Main Products: Industrial Polymers, Eethylene Vinyl Acetates

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowPolythlene- HDPE, LLDPE, LDPE

Primarily used in packaging industry, our Polythene- HDPE, LLDPE, LDPE, is derived by accurate composition and reaction of various carbons and its compounds.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

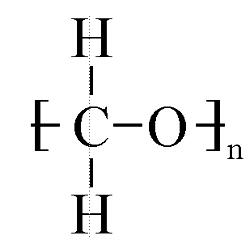

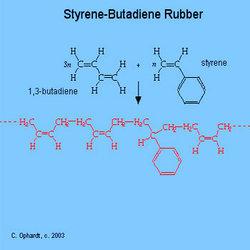

Primarily used in packaging industry, our Polythene- HDPE, LLDPE, LDPE, is derived by accurate composition and reaction of various carbons and its compounds. Based on its density and branching, this polythene is processed to form various categories like HDPE, LLDPE, LDPE and others. Extrusion is the most common process used for LDPE (tube, blow and cast films, cables) where as it can also be processed by injection molding or roto-molding.

Extrusion:

Melt temperature : 180-240 C

Higher melt temperatures are needed for extrusion-coating (280-310 C)

A three zone screw with a L/D ratio of around 25 is recommended

Injection molding :

Melt temperature : 160-260 C

Post mold shrinkage lies between 1.5 and 3.5%

Images