Dr Polymers Ltd

Product Range

Fact Sheet

- Location:New Delhi, India

- Year of Establishment:1978

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Turnover:Rs. 50 - 500 Crore

(or USD 10 Million - USD 100 Million) - Main Products: Industrial Polymers, Eethylene Vinyl Acetates

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

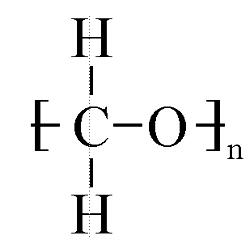

Verify NowPOM - Polyacetal

Partially crystalline thermoplastics, POM – Polyacetal finds application during manufacturing of engineering precision parts, which require high stiffness, low friction and excellent dimensional stability.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Partially crystalline thermoplastics, POM – Polyacetal finds application during manufacturing of engineering precision parts, which require high stiffness, low friction and excellent dimensional stability. Mechanical properties of POM are determined by the degree of crystallization, which increases with the mold temperature. Similar to all crystalline polymers the follow-up pressure can be influential on the shrinkage of the part and a longer hold time is preferred to reduce shrinkage.

Injection Molding:

Mold temperature of 50 – 120 C

MFI (190C @ 2,16 kg) = 1 – 10 kg/10 min POM is suitable for injection of thin wall & complex parts, MFI (300 C @ 21,6 kg) of 13 – 65 g/10min

Extrusion:

Extrusion mainly to produce semi-finished articles (round and flat rods, hollow rods, slabs) and can be carried out easily on single and multi screw extruders

Extrusion temperature : from 180 to 220 C.

A L/D ratio of 15 to 25 is recommended.

MFI (190C @ 2,16 kg) = 1.3 kg/10min

Images