Alfa Engineering Works

Product Range

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:1999

- Business Type:Manufacturer

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Industrial Machines, Oil Expellers

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

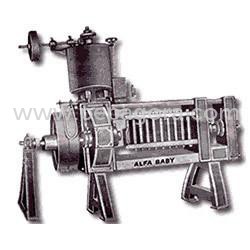

Verify NowAutomatic Giant Oil Expeller

This popular 'ALFA' production is the result of long experience in the manufacture of Oil Expellers and the need of oil millers in home and foreign markets.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

This popular 'ALFA' production is the result of long experience in the manufacture of Oil Expellers and the need of oil millers in home and foreign markets. It provides and oil extraction unit of highest efficiency combined with simplicity of operation. Several important features of all the leading types of expeller have been included in the design of this expeller. This contributes towards ease of manipulation, vertically hinged chamber box, simple mechanical cone operating mechanism and easy withdrawal of main shaft. Soundness of design coupled with careful selection of rawmaterial and highest quality of workmanship make the 'ALFA AUTOMATIC GIANT EXPELLER unequaled for accessibility, freedom from mechanical trouble, durability and for low cost of maintenance and labour. Outstanding features of “ALFA AUTOMATIC GIANT EXPELLER” are as under:

Fabricated Bed: To ensure perfect alignment and stability, the machine has a heavy one piece steel bed requiring little in the way of foundation.

Vertically Hinged Chamber Box: This is a unique improvement. The difficult and laborious task of removing the chamber for relining it or for replacement of worms is entirely eliminated as the chamber need never be removed from the machine for any purpose whatsoever. This result in great saving of time and labour.

Easy Shaft And Worms Withdrawal: whenever the main worm shaft is to be withdrawn, this can be easily done without disturbing the driving gear in any way and pressure worms can be changed even without disturbing or withdrawing the main shaft. The thrust of the pressure worms is taken by a large Ball Thrust Bearing which is not disturbed when either shaft or worms are changed. The main worm shaft is of stepped design to assist easy removal of worms and collars.

Preliminary Compressor: The feed is under perfect control and as the cooked meal enters the Expeller, it receives preliminary compression and is consolidated before entering the chamber box, resulting in immediate oil extraction. The preliminary compressing worm is driven by an automatic tension belt which stops it when the feed is excessive, starting it again when the accumulation has been taken up by the expeller.

Durability: All parts subject to heavy wear and tear such as worm, cage bar, cone point etc, are made from Cast hardening Steel and prperly heat treated to give long life, high capacity and low maintenance cost.

Water Cooled Shaft: For certain oil seed such as Copra, Palm kernels etc, water cooling of the main shaft is recommended. The same can be fitted at an extra cost.

Belt And Motor Drive: ALFA Automatic Giant Expeller can be driven can by belt in any number from one main shaft, each expeller can be fitted with its own electric motor mounted upon it. Where electric drive is preferred. Customer should give full details of the electric supply available.

Cooking Kettle: The Expeller is fitted with a two State cooking kettle compact design which affords ample cooking capacity under all normal condition, the kettle is fitted with a self controlled meal in inlet to prevent overflowing. It is fitted with steam damping apparatus, safety valve, steam pressure gauge, condensate, drain with efficient steam traps and steam valves. The kettle requires 35-45kg. Of process steam per hout at a pressure of 60lbs. Per square inch.

Power: The power required depends upon the material being crushed and the extent to which it has been prepared prior to being fed to the cooking kettle. Normally in first pressing of cotton seed, linseed, groundnut, copra, mustard etc., it require 40B.H.p. Ball bearing of good make are fitted everywhere, to reduce the consumption of high power.

Images