Alfa Engineering Works

Product Range

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:1999

- Business Type:Manufacturer

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Industrial Machines, Oil Expellers

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

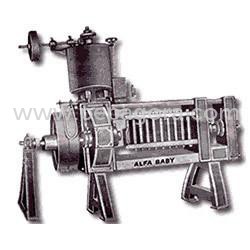

Verify NowOil Expellers Mark 20 And Mark 30

ALFA oil machinery is being used satisfactorily in India and many overseas countries for over 40 years. Our models in corporate the latest international design specifications and technological developments.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

ALFA oil machinery is being used satisfactorily in India and many overseas countries for over 40 years. Our models in corporate the latest international design specifications and technological developments. The enhanced efficiency thus obtained gives you savings in terms of time, money and labour.

ALFA mark 20 OIL expeller and ALFA mark 30 oil expeller , our 2 recent models, meet the demand of high capacity high yield expellers.

Our designers have spared no effrot to make these models strong and sturdy. ALFA OIL MACHINERY is easy to install and gives you long trouble-free service.

ALFA-MARK 20, mark 30 oil expeller

Crushes in a single pressing operation approximately 20 tons to 30 tons oil seeds in 24 hours and leaves behing 5% to 6% oil in the cake.

MARK – 20

This expeller has 2 chambers of 22* and 33* length having worm diameters of 9* and 8*

MARK – 30

This expeller has 3 chambers of 36*,33* and 24* length having worm diameters of 12*,10* and 9*

Chamber Box

Being vertically hinged it opens like a book and saves the trouble of removing it from expeller during change or worms. This is great time and labour saving improvement.

Cooling Of Chamber

Oil from the oil setting tank is pumped and sprayed by a special motorised pump which is part of the standard equipment. Oil thus flushed on the chamber removes the foots and also cools the chambers. As a consequence the life of the spare parts is enhanced.

Gear Box

The gear box is robust and of close grained C.I. Casting fitted with heavy bearings and tempered helical steel gears which run in oil bath. These hobbing cut teeth gears run silently and have long life.

Body And Center Bodies

These are fabricated from tested steel plates.

Preliminary Compression

The cooked meal from kettle is compressed and consolidated by packing worm before entering the chamber box, where oil extraction starts immediately. The packing worm is driven by automatic tension belt which stops whenever the feed is excessive and starts again as the accumulated material has been taken over the feed worm.

Main Worm Shaft With Water Cooling Arrangement

The worm shaft is of special alloy steel of high tensile strength of withstand shock and strain. It is stepped in design to assist easy withdrawal of worms ans collars. The shaft can be removed without disturbing the main thrust bearing and main gears. It is equipped with necessary motorised pump for water cooling arrangement.

Cooking Kettle

Mark – 20

The expeller is fitted with FOUR stage cooking kettle, it is compact in design and is fitted with self controlled meal inlet to prevent overfedding, it also fitted with a safety valve, a pressure gauge, steam traps, a steam valve and steam damping apparatus. It is independently driven by 20 HP motor through a reduction gear box.

Mark – 30

The expeller is fitted with FIVE stage cooking kettle. It is compact in desing and fitted with self controlled meal inlet to prevent overfeeding. It also fitted with a safety valve, a pressure gauge, steam traps, a steam valve and steam damping apparatus. It is independently driven by 20 HP motor through a reduction gear box.

Flow Of Oil And Foots From Expeller

A conveyor is provided in the oil tray of the expeller which conveys oil and foots to oil storage tanks.

Images