Storage Solutions

Product Range

Fact Sheet

- Location:Karnataka, India

- Business Type:Distributor / Wholesaler, Business Services

- Main Products:Bolted Panel Water Tank,Glass Fused Steel Tank,Stainless Steel

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

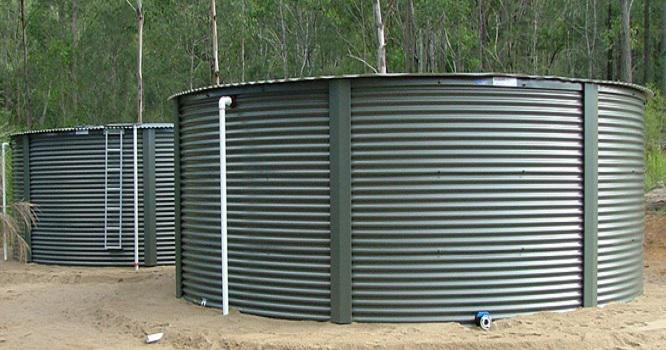

Verify NowBolted Panel Water Tank

Bolted panel water tanks are bolted / interior design, prefabricated, prefabricated and assembled on site. Our proposed water tanks are designed to meet or exceed the expected life of the project for which they are created.

- Payment TermsCash,Cheque,Demand Draft

Product Details

Type

Water TankPrice

NegotiableDelivery

On Time DeliveryApplications

Industrial ApplicationsConstruction

Strong And SturdyTank Type

Bolted PanelWelding

AS/NZS 1554-2008Cathodic protection

AS/NZS 4680-2006Fire protection application

AS 2304-2011Nozzles

AS/NZS 4680-2006Platforms and Ladders

AS 1657-1992Roof

AS/NZS 1170-2007, 4100, 4600Tank Structural Design

AS/NZS 1170-2007, 4100, 4600

Other Details

RHINO bolted panel liner tanks are of vertical cylinder design, and are of a unique two-part construction , in which the contained water or other liquid never comes in contact with any material that is subject to corrosion. This construction results in a zero-maintenance or nil- maintenance tank, with a design life of more than 50 years. The external, cylindrical shell is of ZincAlume steel, having very high corrosion resistance. Inside the shell is a containment bladder constructed out of a multiple-layer liner material fabricated from polyethylene, with a woven fabric reinforcement layer and a backing layer of Metallocene.

The tanks are available in capacities: 10,000 (10 kl) litres to 2,500,000 (2500 kl). RHINO bolted panel liner tanks are superior to both RCC tanks (plain or lined) and welded-steel , rubber-lined or epoxy-painted tanks with regard to design life, maintenance, maintenance cost, maintenance downtime, life-cycle cost, re-sale value, residual value and scrap value.RHINO tanks can replace RCC tanks and welded-steel tanks in most – if not all – applications, and are a very cost-effective substitute.

APPLICATION INCLUDE:

(1) Vegetable oil and animal oil storage

(2) Sewage treatment and waste water treatment

(3) De-mineralised water storage.

(4) R.O. Plant

(5) Fire-protection water storage

(6) Rain water harvesting

(7) De-salination plant

(8) Raw water storage and treated water storage – municipal and domestic

CONSTRUCTIONAL DETAILS:

Material of Construction

(1) Shell

Special grade corrosion-resistant BlueScope ZincAlume Steel. (For more details about"BlueScope Steel" please click here. BlueScope.pdf)

(2) Inner Liner

Multi-layer, reinforced, Metallocene-backed pulyethylene sheet. (For more details about "HydraShield Liner" please click here HydraShield.pdf)

Tank Body

Rhino Bolted-Panel Liner tanks have a two-part construction:

(1) Outer shell: Constructed of corrugated ZincAlume steel from BlueScope Australia, having four times the life span of GI sheet, and much higher resistance to weather and corrosion. The shell has multiple layers of ZincAlume sheet, for structural strength. The exact number of layers depends on the height and diameter of the specific tank. The corrugated construction increases the hoop stress withstand of the steel sheet, so that less material is needed to achieve the same performance. The shell segments are Bolted together with 12 mm hot dip galvanised bults. For details of ZincAlume steel from BlueScope

(2) Inner liner:Multiple-layer, reinforced pulyethylene sheets backed by a layer of high-impact resistant Metallocene. Reinforcement with woven scrim fabric to This construction ensures that the liquid/water contents never come into contact with steel shell, to reduce the possibility of internal corrosion to zero.

Tank Roof : Constructed of ZincAlume or GI corrugated sheet, supported over Hot-Dip-Galvanised roof trusses.

Corrosion protection: BlueScope ZincAlume steel has coating of Zincaluminium Alloy, 55% Zinc, 42.5% Aluminium and 2.5 % silicon. Zinc provides sacrificial protection, Aluminium provides barrier protection, and silicon provides abrasion resistance.

Back-up Corrosion Protection : Protection by the use of sacrificial magnesium anodes.

Tank foundation (Customer Scope): Simple ring-beam foundation in RCC. Drawings provided by Rhino Tanks.

Standard Accessories

(1) Inlets and outlets: One outlet nozzle of appropriate size, one scour drain outlet nozzle and one bell-mouth overflow outlet are provided as standard.

(2) Additional inlet/outlet/other nozzles can be provided at extra price.

(3) Level Guage

(4) Common internal/external ladder

(5) Sacrificial anode.

(6) Lockable Access hatch

Optional Accessories

(1) Platform with caged ladder

(2) Inlet deflector

(3) Rainsaver

(4) Anti-vortex fittings

(5) Manway

(6) Fire-fighting coupling

DESIGN CODES AND STANDARDS:

Rhino Tanks comply fully to the requirements of the Building Code of Australia and to following Design Codes and Standards

|

Tank Structural Design |

AS/NZS 1170-2007, 4100, 4600 |

|

Inner liner |

AS/NZS 4020:2005 ANSI NSF 61-2008 |

|

Roof |

AS/NZS 1170-2007, 4100, 4600 |

|

Platforms and Ladders |

AS 1657-1992 |

|

Nozzles |

AS/NZS 4680-2006 |

|

Welding |

AS/NZS 1554-2008 |

|

Cathodic protection |

AS/NZS 4680-2006 |

|

Fire protection application |

AS 2304-2011 |

Images