M K Enterprises Nangloi

Company Overview

Fact Sheet

- Location:New Delhi, India

- Year of Establishment:1981

- Business Type:Business Services

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Powder Coating Services, Phosphating Services

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowCompany Info

Overview

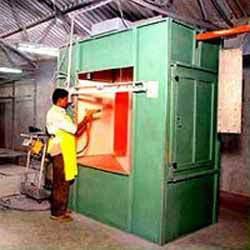

Established in the year 1961, we M. K. Enterprises is an organization engaged in undertaking Powder Coating & Phosphating Services. Supported by our skilled and experienced professionals, we also provide complete in-house solution for our esteemed clients. We started its journey in 1962 under the name of "Stoving Spray Painting Works" at Anand Parvat. Initially we started as a paint company but in1982 we expanded our domain and also started powder coating business under the name of “M. K Enterprises”.

We are doing proper pretreatment process that is 7 tank process for M/S CRC and chromate for alluminium. The size of the phosphating tank are 9.5x5.5x3 foot and chromate tank size 19x2x3 foot.

Also we are having 7 plants of different sizes which are working continuously day and night/24*7

Our services are executed using latest methodologies and caters to the needs of storage systems, furniture, shelving systems, retail chain store, metal handicrafts, sheet metal components and automobile parts.

Under the guidance of our founder, Mr Haji Manzoor Khan who holds 48 years of experience in this domain, we have gained the new heights of success. His rich experience and transparent dealings have helped us to garner a huge clientele all across the country. Some of our esteemed clients are Nestle, Maruti, Crompton, Greaves, Hero Honda, Coca Cola, DMRC, Northern Railway, Bharat Petroleum and Adani Gas Pvt. Ltd.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin." The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as "whiteware", aluminium extrusions, and automobile and bicycle parts. Newer technologies allow other materials, such as MDF (medium-density fibreboard), to be powder coated using different methods.

Phosphate coatings are used on steel parts for corrosion resistance, lubricity, or as a foundation for subsequent coatings or painting. It serves as a conversion coating in which a dilute solution of phosphoric acid and phosphate salts is applied via spraying or immersion, chemically reacts with the surface of the part being coated to form a layer of insoluble, crystalline phosphates.Phosphate conversion coatings can also be used on aluminium, zinc, cadmium, silver and tin.