MERIT Industries Limited

Product Range

Fact Sheet

- Location:Tamil Nadu, India

- Year of Establishment:1996

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Material Handling Equipment, Hydraulic Baling Press

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

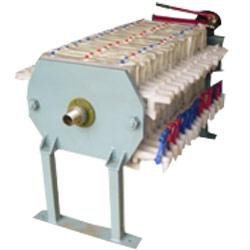

Verify NowRubber Moulding Press

The heavy duty Rubber Moulding Press manufactured by us is in great demand for increases product manufacture, advance quality, reduced manpower, electric power, rejection time & space.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

The heavy duty Rubber Moulding Press manufactured by us is in great demand for increases product manufacture, advance quality, reduced manpower, electric power, rejection time & space. These molding presses offer uniformity of product quality. as they convey the same specialized form every time they are used. The Rubber Molding Press we offer can be availed in both up stroking and down stroking types. We offer both standard and customized options in this range to meet the specific requirements of clients.

Features:

- The low noise hydraulic power pack unit is designed as per ISI guidelines & assembled using branded valves & components

- The press has precisely honed carbon steel seamlessq tubes, assembled with hard chrome plated piston rods and sealing elements of EN-9 & international standards

- Manifold blocks are mounted on valves minimizing piping, leading to no leakage & easy replacement & maintenance

- During curing period, the electric motor stops & starts depending on the pressure, while maintaining the pressure. Therefore there is less strain on the hydraulic system

- Advanced designing & accurate assembly using improved technology leads to efficiency in electricity usage, less noise, less pollution and improved product quality

- Platens tested ultrasonically and are used of heavy thickness to make the frame more rigid & strong to take load during frequent & fast operations

- Right angularity between bed & the moving platen is maintained

Product Application

- Rubber products (automobiles, medical equipment etc.)

- Plastic sheets molding

- Laboratory applications

- Composite materials moldings (Bullet proof Jackets, Helmets, etc.)

- Melamine Crocking Molding

- Ply board, MDF sheets, Particle Boards etc.

- Conveyor Belts / V-Belts, Rubber mats / Flaps/ Tyres / tubes etc.

Images