Khosla Machines Pvt Ltd

Product Range

Fact Sheet

- Location:Punjab, India

- Year of Establishment:1983

- Business Type:Manufacturer, Exporter

- Main Products:Soap Packing Machines , Biscuit Packing Machines

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

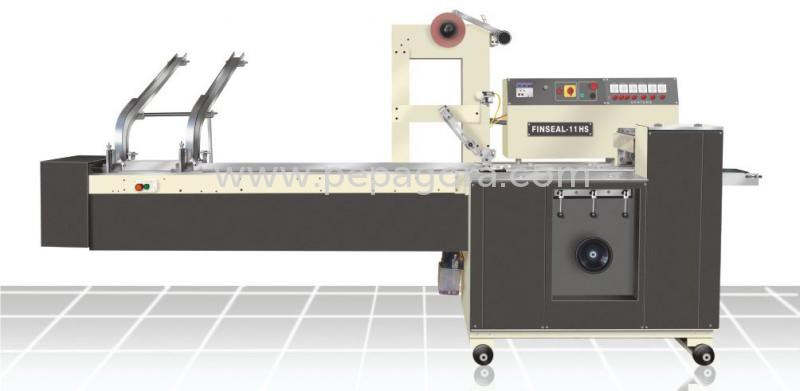

Verify NowFinseal 11hs

PRINCIPAL OPERATION: FINSEAL 11 HS flow wraps piles of twin biscuits(1 to 4 biscuits in a pile). Biscuits are drawn from the bottom of twin magazines, which are adjustable for different sizes of biscuits.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

PRINCIPAL OPERATION:

FINSEAL 11 HS flow wraps piles of twin biscuits(1 to 4 biscuits in a pile). Biscuits are drawn from the bottom of twin magazines, which are adjustable for different sizes of biscuits. Infeed conveyor transfers the biscuits into wrapping film that has been formed into a tube by means of forming folder. Bottom seal is made by three sets of rollers. Cross sealing and cutting knife separate the packed biscuits. Heat sealable material like BOPP or laminates is used for wrapping. Output can either be individual packs or chain packs.

STANDARD FEATURES

- All surfaces over which biscuits are transported are made of stainless steel

- Long seal is formed by means of three pairs of rollers, axes of which can be tilted to get best results

- Low voltage heaters for safety

- Twin cutting knives for high speed operation

- Individual, digital PID temperature controls for all heaters

- Automatic centralized lubrication

- Print registration unit for printed wrapper

- Heavy distortion-free cast structure

HIGHLIGHT

- Date printing unit

- Variable speed drive (AC frequency control)

- Castors for mobility of machine

- Parallel to infeed conveyor orientation of magazines

- Twin pile packing arrangement

- Machine speed upto 250 PPM infinitely variable.

Images