Kaps Engineers

Company Overview

Fact Sheet

- Location:Gujarat, India

- Year of Establishment:1965

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

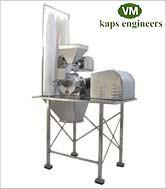

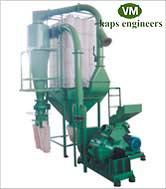

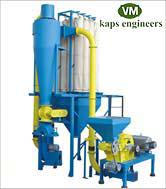

- Main Products: Pulverizer , Size Reduction Equipment

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowCompany Info

Overview

Our Philosophy

To provide total solution to our customers within his constraints

To make Kaps Engineers a most preferred company in the area of core competency

Transact business with fairness, trust transparency and judiciously

Create partnership of trust for mutual growth with Employee, Suppliers, Vendors, Bankers, Customers and Business Associates

Avoid any business activities leading to killing of living creatures

Our Promoters

Kaps Engineers is a family managed company. Mr. V. M. Mehta (B.E. Civil, A.M.I.E., USA), a visionary and technocrat, is behind the foundation of Kaps Engineers. He pioneered this company in the year 1965 at Mumbai.

In the year 1971, Mr .Anil Mehta, B.E.(Mech.) and Mr. Mahesh Mehta, B.E. (Mech.) - M.S. (Operations Research, USA ) - sons of Mr. V. M. Mehta, have taken over the charges of the operations of company.

In the year 1996 Amish Mehta - son of Mr. Anil Mehta, and in the year 2003 Shrenik Mehta - son of Mr.Mahesh Mehta have joined the company.

In the year 1982, the additional business activity started at Vadodara, Gujarat. Since 2003 total business activity was centralized at Vadodara.

The brand name of "VM" is well know in the size reduction equipments market globally. Kaps Engineers is a well know manufacturer and exporter of Size Reduction Equipments. Our business is further reinforced by the principle of "Import Substitution through excellence".

Marketing Excellence

M/s. Batliboi & Company Ltd. were our main selling agents till the year 1992. Later on, looking at the changing market trends and our growth prospects, we switched on to direct marketing activities since 1992. This facilitated us with an increase in the market share and facilitating direct contact with our valued customers. Marketing activities of VM products are being supported by a wide network of Marketing Associates all over India and Abroad.

Our Organization Strength

- Existence in the business since 1965.

- Installed more than 6500 units in Domestic and Foreign markets.

- More than 6500 Trial and Test data.

- Exports to various countries

- Full fledged Trial and Test Facility

- 50- 70% of our annual business is from our past users

- 10 - 20% of annual business from overseas buyers

- Total Quality Management is being practiced since 1996.

Our Operation Areas

Our Size Reduction Equipments have vivid industrial applications. This is a challenge for us and we have been dealing with it effectively for decades. Catering to the needs of various industrial needs, we design our products in such a way that they are easy to install, easy to operate and can be maintained at a very low cost. Some of our specific operation areas include -

- De-lumping of lumps

- Coarse to micro fine grinding with screen type and screen less equipments

- Feeding devices like screw feeders, belt feeders, vibratory feeder & rotary feeders

- Conveyors like Screw Conveyors, Vibratory Conveyors, Belt Conveyors, Pneumatic Conveyors

- Rotary Air Lock Valves

- Dust Collectors such as Open Type Dust Collector, Pulse Jet Dust Collector

- Particle Separators like Sieve Separators and Air Classifiers

Core Competency

- Cool Grinding Equipments

- Stainless Steel GMP Grade equipments

- Explosion proof equipments

- Equipment for minimum intermittent handling

- Pharma Milling equipments (Stainless Steel GMP Grade)

Product Advantages

- Low Power consumption

- Reduced multiple handling

- Minimum products losses

- Eco-friendly equipments

- Optimum capacity utilization

- Narrow band grade distribution of powder

- Equipment for minimum intermittent handling

- Minimum running maintenance for the equipments.