Flomech Valves

Product Range

Fact Sheet

- Location:West Bengal, India

- Year of Establishment:1992

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Turnover:Upto Rs. 50 Lakh

(or Upto USD 100 K) - Main Products:Industrial Valves, Marine Valves

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowDiaphragm Valve Straight Through Type

Originally, the diaphragm valve was developed for use in industrial applications. Later on the design was adapted for use in the bio-pharmaceutical industry by using compliant materials that can withstand sanitizing and sterilizing methods.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

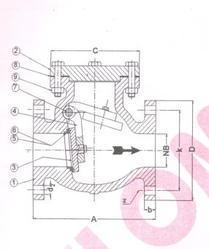

Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, a diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve is constructed from either plastic or metal.

Originally, the diaphragm valve was developed for use in industrial applications. Later on the design was adapted for use in the bio-pharmaceutical industry by using compliant materials that can withstand sanitizing and sterilizing methods.

There are two main categories of diaphragm valves: one type seals over a "weir" (saddle) and the other (sometimes called a "full bore or straight-way" valve) seals over a seat. The weir or saddle type is the most common in process applications and the seat-type is more commonly used in slurry applications to reduce blocking issues but exists also as a process valve. While diaphragm valves usually come in two-port forms (2/2-way diaphragm valve), they can also come with three ports (3/2-way diaphragm valves also called T-valves) and more (so called block-valves). When more than three ports are included, they generally require more than one diaphragm seat; however, special dual actuators can handle more ports with one membrane.

Images