Conex System

Product Range

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:1991

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Power Electronic Instrument, Electronic Equipment

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

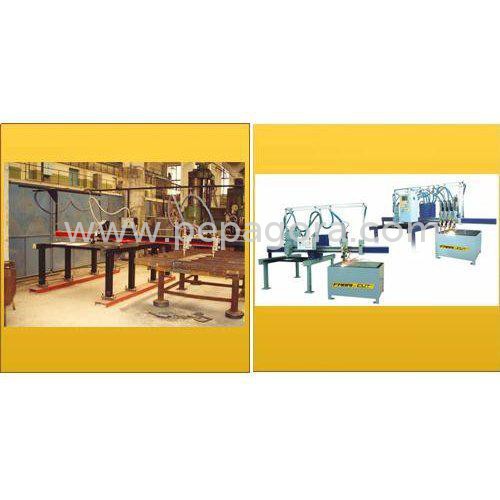

Verify NowCNC Plasma Cutting Machines

Plasma cutting has long been seen as a low cost alternative to oxy-fuel and laser profiling where cut angle was not an issue.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Plasma cutting has long been seen as a low cost alternative to oxy-fuel and laser profiling where cut angle was not an issue. Recent developments in the high precision/high definition plasma process have significantly improved the quality and capabilities of plasma cutting, making it a more versatile and accurate option than ever before.

Application Suitability:

- Plasma cutting is suitable for various materials particularly mild steels and stainless steels producing an excellent edge finish.

- Enhancements to the control systems now mean that optimum cutting performance for a range of materials and thicknesses from 1mm to 32mm in mild steel (dependent upon the power of the plasma unit) can be achieved.

- Parameters associated with cutting a wide range of materials and thicknesses such as cutting speed, gas types and gas pressures can now be controlled automatically by the Kerf equipment, ensuring a consistently high cut quality.

- Users now have a truly cost effective alternative to other cutting processes.

CNC Plasma Cutting machine comes in 4 types:

- Fabri Plasma Cut-S Machine

- Fabri Plasma Cut-S Machine

- Arc Voltage Height Controller

- Plasma System (With 'PLUS' Technology)

Images