Bharmal Traders

Product Range

Fact Sheet

- Location:Madhya Pradesh, India

- Year of Establishment:1972

- Business Type:Manufacturer, Exporter, Business Services

- Turnover:Rs. 50 Lakh - 5 Crore

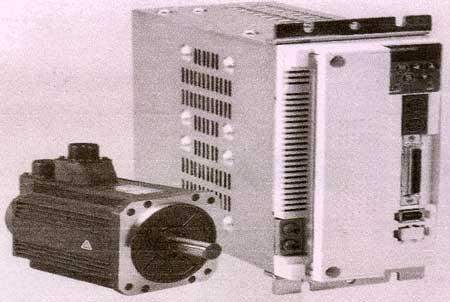

(or USD 100 K - 1 Million) - Main Products:A.C. Drives, Control Panel Boards

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

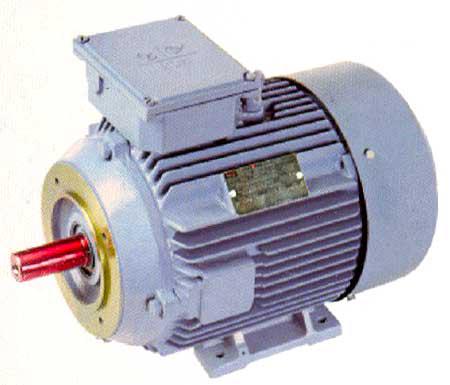

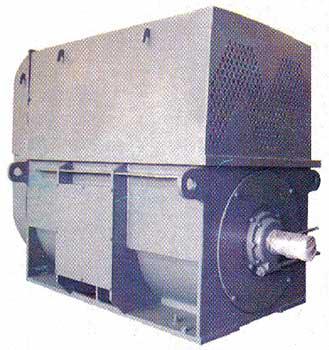

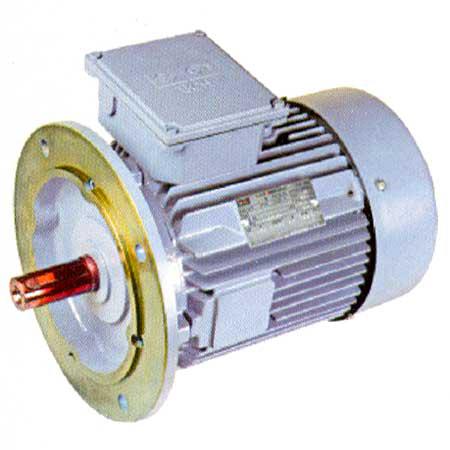

Verify NowVertical Motor01

We are the foremost vertical electric motor supplier, incepted in India.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

We are the foremost vertical electric motor supplier, incepted in India. Our vertical hollow shaft motor is highly durable and widely acknowledged in the market for its performance. Our vertical motor is made from the optimum quality raw material and is termed as one of the bests in the market.

OXFORD Motors is proud to introduce the IP55 Metric Motor line of rugged, all-purpose motors. The cast iron, totally enclosed fan cooled IP55 construction makes this motor the preferred choice for almost any application in even the toughest environments.

Standard Ratings : 2,4,6,8,10 Poles upto 5000

Standard :

Built to meet or exceed the IEC standards for dimensions and performance.

IEC 34 – 1 Performance

IEC 72 Dimensions

IEC 34 – 5 Degree of protection

Efficiency :

Confirm to EFF-2 level and are CE marked.

Power Supply :

For greater application flexibility and increased safety margin our motors are suitable for 415V+/-6%, 50Hz + /-5%, combine variation allowed + /-10%

Ambient Temperature :

-15 TO 45 degree C is standard

Service Factor :

These motors have a 1.15 S.F. at 50Hz, typical for IEC motors, Duty class S 1.

Construction :

The rugged cast iron construction of the frame, end- shields, integral feet and flanges absorbs Shock and reduce motor vibration to provide a low- maintenance motor life.

Terminal Box :

The terminal box is of cast iron construction and is available on Top.

Stator Winding and Insulation :

The stator core is built up from low loss, high permeability, silicon steel for increased efficiency. It features a class F insulation system with design for class B maximum temperature rise.

Rotor :

The rotor is built with the same high quality lamination steel, die cast with high conductivity aluminum, Shrunk fit on to a high strength carbon- steel shaft. The rotor assembly is dynamically balanced to provide low noise and smooth, vibration-free operation for long trouble free life.

Bearings :

All motors used 100,000 hours direct coupled /25,000 hours belted, anti- friction, deep- grooved ball Bearings of 63 series, on drive end, tight fit.

Cooling Method :

ICO 141 bi directional cooling fan.

Connection :

Star-connection for up to 3kw, delta-connection for 4kw and above.

Warranty :

Oxford motors are warranted to be free from defects in material, workmanship for a period of one year.

Product Application

Material handling

Fans, Blowers

Lifts

Valve actuators

Saw mills

Cranes

Granite / Marble / Stone industry

Machine tools

Agro industry

Stone crushers

Fertilizers

Textiles

Food processing

Pulverisors

Compressors

Pumps

Gear drives

Flour mills

Solvent plant

Sugar mill’

Roling mill

Available in all standard manufacturing company as Crompton, Kirloskar, Simence, Hindustan ABB.

Images