Amarshiv Engineering Company

Product Range

Fact Sheet

- Location:Gujarat, India

- Year of Establishment:1996

- Business Type:Manufacturer, Exporter, Business Services

- Turnover:Rs. 5 - 50 Crore

(or USD 1 Million - USD 10 Million) - Main Products:JAW CRUSHERS,VSI CRUSHERS,Toggle Jaw Crusher,Double Toggle Jaw

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

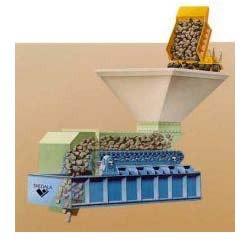

Verify NowGrizzly Feeder

We are engaged in the manufacturing, supplying and exporting of premium quality Grizzly Feeder. These feeders are precisely manufactured under the supervision of qualified professionals using fine quality material.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

We are engaged in the manufacturing, supplying and exporting of premium quality Grizzly Feeder. These feeders are precisely manufactured under the supervision of qualified professionals using fine quality metal that is sourced from trustworthy vendors. Appreciated for their seamless finish, rust resistance and optimum performance, these feeders are highly demanded in material handling industries.

A vibratory feeder is an instrument that uses vibration to "feed" material to a process or machine. Vibratory feeders use both vibration and gravity to move material. Gravity is used to determine the direction, either down, or down and to a side, and then vibration is used to move the material. They are mainly used to transport a large number of smaller objects.

A belt weigher are used only to measure the material flow rate but weigh feeder can measure the flow material and also control or regulate the flow rate by varying the belt conveyor speed.like in rsp coke oven

Industries Served[edit]

Versatile and rugged vibratory bowl feeders have been extremely used for automatic feeding of small to large and differently shaped industrial parts. They are the oldest but still commonly used automation machine available for aligning and feeding machine parts, electronic parts, plastic parts, chemicals, metallic parts, glass vials, pharmaceuticals, foods, miscellaneous goods etc. Available in standard and custom designs, vibratory bowl feeders have been largely purchased by varied industrial sectors for automating high-speed production lines and assembly systems. Some of the industries that use the service of this automation machine include:

* Pharmaceutical

* Automotive

* Electronic

* Food Processing

* Fast Moving Consumable Goods (FMCG)

* Packaging

* Metal working

* Glass

* Foundry

* Steel

* Construction

* Recycling

* Pulp and paper

* Plastics

With these easy-to-use and high performing part feeding machines, customers from varied industrial sectors have achieved lower error rates, lesser power consumption, better profits, better rates of efficiency and less dependency on man power.

Technical Specifications

- Sizes Available: 6' x 3' to 14' x 3'

- Maximum input Size: 1200 mm

- Minimum input Size: 400 mm

Images