Frontline Roll Forms Pvt Ltd

Product Range

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:1993

- Business Type:Manufacturer

- Main Products:Cold Roll Formed Sections, Pre. Engineering Building

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowCold Roll Formed Section

Cold Roll Formed Section is the most efficient method of converting sheet steel intc desired shapes through a gradual process of bending by a number of specially designed rolls mounted on a cold forming mill.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Cold Roll Formed Section is the most efficient method of converting sheet steel intc desired shapes through a gradual process of bending by a number of specially designed rolls mounted on a cold forming mill.

In addition to the universal profiles, like channels and angles, the cold-formed sections offer tremendous potential for cutting cost, through superior design of shapes and flexibility of sizes. We, at FRONTLINE, have the ability to design and also have manufacturing capacity to offer many innovative solutions in specific application areas, like factory building structural, conveyor systems, material handling, pallet racking systems, porta cabins and truck chassis members etc.

The technology has many advantages over the conventional press brake method of forming namely :

Cold working capitalizes on the steel's tendency to become harder and stronger when formed while cold. This gives an added advantage to cold-formed sheet steel because the shaping process actually makes the part stronger.

It achieves a better consistency and accuracy of profile.

The possibilities of producing the variety and range of Shapes are almost unlimited, determined only by the number of stations available on the mill and the ability of the tool designer. Indeed some shapes can not be produced by any other method.

Cold roll formed sections do not suffer from the length constrains and can be supplied to your exact requirements.

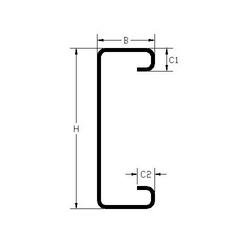

HAT SECTION:

As truss member, secondary members (column lacing, tie runner and wind bracing) in pre-fabricated building.

Fencing for boundary wall.

We contribute to enhancement of productivity through optimal utilization of steel, some examples:

Substituting hot rolled conventional sections by specially configurated steel saving shapes, in end uses like roof purlins, side claddings and mezzanine floor structurals.

Substituting press brake bent, simple shapes by improvised profiles with superior properties, in ^ applications like racking systems, material handling, cable trays and conveyor systems.

Product Application

As a secondary member (Purlin, Girt) in industrial building. Structural in cabin and containers

As Guard rail spacers.

As Racking frames and beams in material handling & storage.

Also in scaffolding, floor joists and also in mezzanine floor structure.

Technical Specifications

Specifications of all sections are as per I.S-811 -1987, SP: 6(5)-1980

High tensile material can also be used.

Images