Abcon Engineering And Systems Private Limited

Product Range

Fact Sheet

- Location:Karnataka, India

- Year of Establishment:1986

- Business Type:Business Services

- Main Products:Engineering & Systems,Engineering & Systems,Information Systems

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowAE&S on its own Lean Manufacturing

Lean manufacturing is also known as lean production. It is a production practice exercised by many organizations to reduce the use of all resources, maximize efficiency and minimize wastage.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Lean manufacturing is also known as lean production. It is a production practice exercised by many organizations to reduce the use of all resources, maximize efficiency and minimize wastage. The term Lean Manufacturing was coined by Daniel T. Jones, James P. Womack and Daniel Roos. The name was derived after they conducted an exhaustive research on the automobile industries worldwide and discovered that the Japanese automotive industries especially Toyota Motor Company utilized less resources with respect to materials, labour, machines, space, capital, inventory etc. Despite this fact, their production capacity was the same compared to their counterparts worldwide. They called this as Lean Manufacturing.

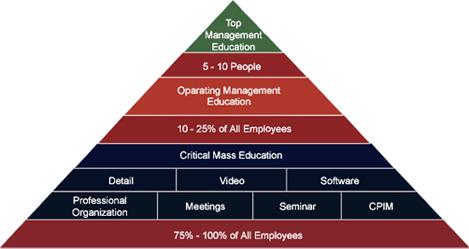

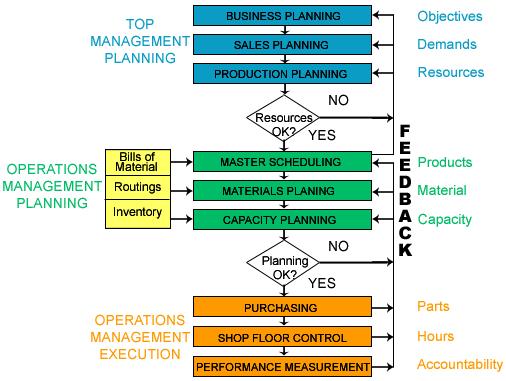

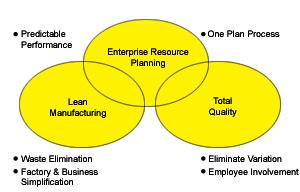

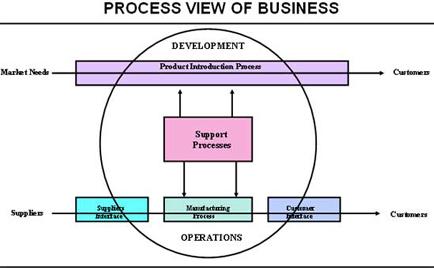

Lean Manufacturing concentrates on areas where there is wastage of time, labour etc. and works towards eliminating them. In the first step Lean Manufacturing implementation, it provides training at all levels that include manufacturing Systems Engineering, Change Management etc. Lean Manufacturing can also be implemented in tools and techniques like total productive maintenance, cellular manufacturing, etc. The key targets of Lean Manufacturing are inventory, movement and unnecessary handling, waiting, physical wastes like scrap, over production, delay in transportation etc.

Six Sigma represents a commitment to provide customer delight through the persistent quest for very high quality like, less than four defects per million parts that are manufactured. By using Design, Measure, Analyze, Improve and Control (DMAIC) they have optimized the utilization of resources to cut down on supply chain costs. The implementation of Six Sigma quality initiatives ensures high quality and customer satisfaction.

Lean Manufacturing and Six Sigma together coordinate activities, monitor performance, provide management oversight, gather statistical information for preventive action, analysis etc. For this, Lean Manufacturing and Six Sigma depend on Information Technology. The measurement systems and management are fully integrated to make Lean Manufacturing and Six Sigma truly effective. Lean Manufacturing and Six Sigma are efficient tools to drive an organization to success and to deliver quality service or products to customers.

Even though the cost and time involved in implementing Lean Manufacturing and Six Sigma is high, the advantages are many. It yields nearly 150 to 800% returns on investments by reduced cost of quality, lower production time, reduce space requirements, lower inventory etc. without compromising on the quality of the product. Once an organization adapts Lean manufacturing and Six Sigma methods it is a perpetual way to drive the organization to success.