Dharti Industries

Product Range

Fact Sheet

- Location:Gujarat, India

- Year of Establishment:1996

- Business Type:Manufacturer, Exporter

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Blanched Groundnuts, Peanuts

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

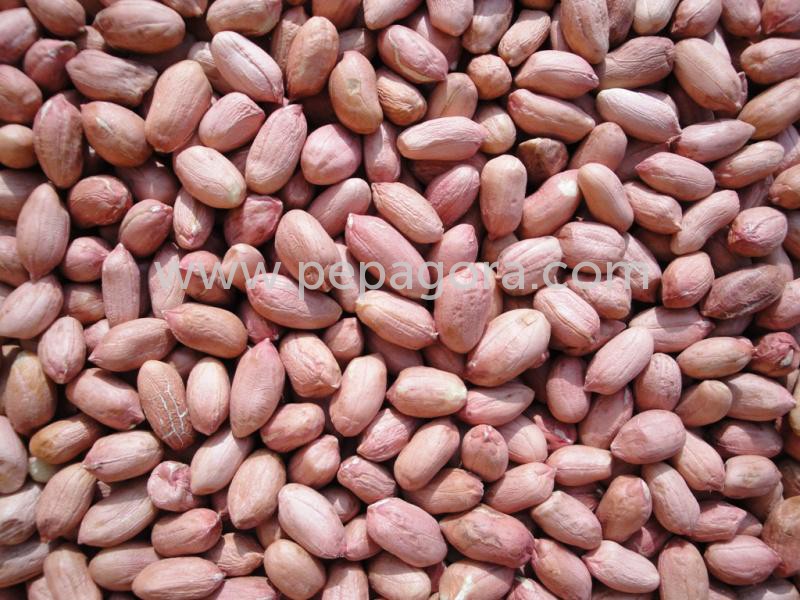

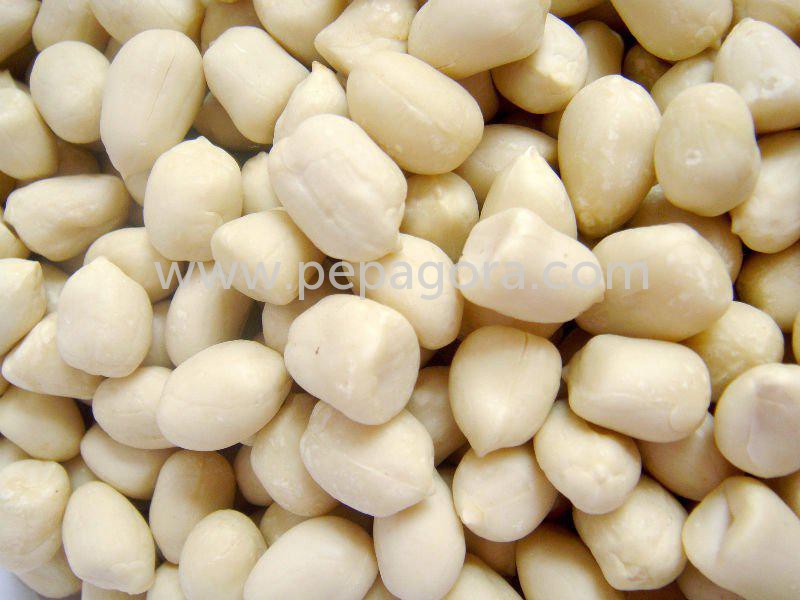

Verify NowBlanched Groundnut Kernels

We are offering our important clients optimum quality Blanched Groundnut Kernels. Groundnut Kernel is used in manufacturing of oil and accounts for major oilseed production in the country.

- FOB PriceNA

- Min Order Quantity1-Kilogram

- Payment TermsNA

Product Details

- Cultivation TypeCommon

- Processing TypeBlanched

- ApplicationFood Indutries

- CertificationNil

- GradeFood Grade

- Shelf Life6 to 12 Months

- StyleFresh

- TasteDelicious

- TypePeanut

- UseFood & Beverage Industry

Other Details

Blanched Groundnut Kernels

We are offering our important clients optimum quality Blanched Groundnut Kernels. The offered kernels are hygienically handled using new approach at our vendor’s production unit. Further, the offered kernels are quality checked by adept experts on the various quality part for ensuring its purity and nutritional content. Furthermore, the offered kernels are highly evaluated amongst our clients for its character and industry leading rates.

Groundnut Kernel is used in manufacturing of oil and accounts for major oilseed production in the country. Offered range is de-shelled, cleaned and stored with good care. This product is quality tested upon various guideline of quality before delivering to customers.

Manufacturing Process:

It includes 5 major steps. They are preparatory systems, Grading & color sorting, Roasting, Blanching, and packaging. In Preparatory systems the Groundnut shells or pods are destined or broken open and groundnut kernels and husk and splits are separated automatically by the latest machines. In the process of grading and color sorting the whole raw nuts are fed into graded according to different sizes or it counts. Then after they pass through color sorting machine to remove infested or unwanted kernels. Further roasting process is done in the roaster at a constant temperature of 60 to 70 C. This is carried out to ensure smooth blanching of kernels and to reduce the percentage of splits during blanching operations. Next in the Blanching process, Removal of outer red skin from peanuts with low pressure. During this process around 20 to 25% peanuts split. Finally, in the Packing section the resultant product is packed per customer specifications. The Packing capacity appropriate to polythene bags and then 2 such bags are packed in a corrugated box.

Unshelled groundnuts can be arranged in cool, dry place for many months, whereas shelled (without the shell) nuts should be placed indoors airtight container and kept inside the refrigerator to bypass them turn rancid.

Images

_6668.jpg)

_6668.jpg)

_6668.jpg)

_6668.jpg)