Astro Mech

Product Range

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:2000

- Business Type:Manufacturer, Exporter

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Pharmaceutical Sterilizing Tunnel, Depyrogenation Tunnel

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

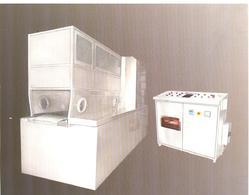

Verify NowPharmaceutical Depyrogenation Tunnel

We are engaged in providing various types of Pharmaceutical Depyrogenation Tunnels, which are used in food & beverages, cosmetics, pharmaceutical and industries across the country.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

We are engaged in providing various types of Pharmaceutical Depyrogenation Tunnels, which are used in food & beverages, cosmetics, pharmaceutical and industries across the country. As per FDA Norms and cG.M.P parameters, our tunnel is specially designed. This completely automatic tunnel has PLC and printer online. The Tunnel is comprised of fine units: The cooling zone The stabilizing zone The infeed drying zone The control panel The sterilizing zone The infeed drying zone: Between vial washing and sterilizing chamber, the drying zone creates thermal barrier to protect the vials from contamination and pre heat the vials. For some hot air, the pressure difference is adjusted to flow from sterilizing zone to drying zone. Hence, drying and pre heating of the vials take place. The sterilizing zone: Up to temperature of 350 Degree C, the sterilizing zone can be heated. Heat is generated with the help of Incoly DS material heating elements. The function of the air temperature and air velocity is sterilizing time of the vials. The air velocity can be adjusted. To obtain a Log-3 pyrogen reduction, the thermal cycle is designed. The cooling zone: Vials enter into cooling zone from sterilizing zone where they are subjected to cold laminar air for lowering the room temperature. Through exhaust blower fitted down the belt, the hot air can be exhausted. The stabilizing zone: To maintain negative pressure in washing room and filling room, the stabilizing zone with cold laminar air flow stabilizing zone is used. The control panel: The Control panel is completely automatic and has Printer On Line and PLC with Sterilizing Temperature Indication. For higher thermal efficiency & power saving, thyristorised temperature control unit is used. Model: With belt width 300mm, 400 mm, 750 mm & 900 mm Output capacity: 90-120 vials / min of 25.4 mm Vials 100-300 Ampoules / Min 60-100 Bottles / Min as per Bottle size Salient features: For depyrogenation & on line sterilization for washed vials & ampoules, stericlean hot laminar flow sterilization tunnel is used Class-100 laminar air flow throughout cooling, drying, sterilizing & stabilizing zone Thyristorised temperature control for power saving & high thermal efficiency with uniform temperature in hot zone Through PLC and online printing, automatic control is attained Output capacity: 90-240 Vials/min 100-300 Ampoules/ min 60-100 Bottles / min

Images